| 【Performance and characteristics】 | 【性能及特点】 |

| The product shall be operated with the principle of vacuum sell-suction, and the liquid is atomized via the nozzle and air until spraying onto working pieces, tools or bearings and other lubricating points. The cooing effects are excellent, and lubrication is provided, as well as scrap removal, cleaning and other functions are used to increase production efficiency and improve processing quality and reduce losses of machinery toors | 该产品采用真空自吸原理,将液体通过喷嘴和空气雾化,喷射到工件、工具或轴承等润滑点上。冷却效果极佳,并具有润滑作用,并具有排屑、清理等功能,提高生产效率,提高加工质量,减少机械刀具损耗 |

| •Cool down in processing, lubricate, and remove iron scrap in one time | •加工冷却、润滑、除铁屑一次完成 |

| • Increase processing rate, save processing time and costs, and reduce wear of knife toots | • 提高加工率,节省加工时间和成本,减少刀齿磨损 |

| • Beneficial for assuring processing quality and application effects of knife toots | • 有利于保证刀齿的加工质量和使用效果 |

| • Processing alloy or super-hard materials achieves smooth and high-precision surface | • 加工合金或超硬材料可获得光滑、高精度的表面 |

| • Pressurization is enhanced to avoid internal leakage and prolong service life. | • 加强加压,避免内漏,延长使用寿命。 |

| • Different foxing modes are used to match different parts | • 不同的零件采用不同的装订模式来匹配 |

| Attentions: | 注意事��: |

| • Clean liquid shall be used. | • 应使用清洁液体。 |

| • Corrosive liquid cannot be used. | • 不能使用腐蚀性液体。 |

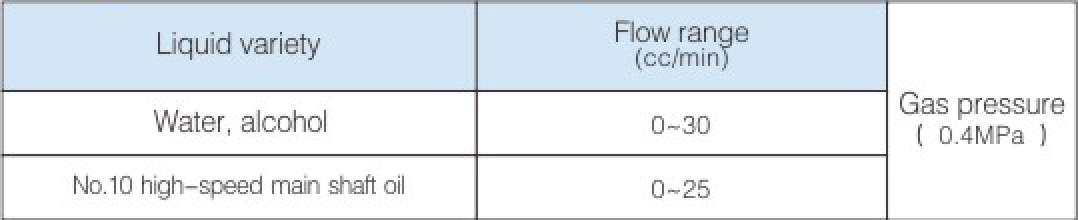

| • Scope of gas pressure of the gas pressure source 0.4-0.6MPa (atomization effects related to air volume and air pressure) | • 气压源气压范围0.4-0.6MPa(雾化效果与风量、气压有关) |

| • Applicable liquid viscosity: 0-32 cSt. | • 适用液体粘度:0-32 cSt。 |

| Situations for application: | 申请情况: |

| • Lathe, drill, mill, grinder, tapping machine, knife tool grinding machine, CNC lathe, punch, sawing machine, woodworker machinery and feeding machine etc. | • 车床、钻床、铣床、磨床、攻丝机、刀具磨床、数控车床、冲床、锯床、木工机械、送料机等。 |

@ 2026 Sino Solutions, All Rights Reserved.