| 【Overview】 | 【概述】 |

| The HLC lubrication pump station is equipped with an electrical program controller, which can be programmed easily. Automatic continuous or periodic oil supply can be realized. It can be used in single-line damping lubrication system (SLR), progressive lubrication system (PRG), quantitative volumetric lubrication system (PDI). Widely used in the lubrication of glass, plastic, machine tools, textile and other mechanical equipment. | HLC润滑泵站配有电气程序控制器,可以轻松编程。可实现自动连续或周期供油。可用于单线阻尼润滑系统(SLR)、递进式润滑系统(PRG)、定量容积润滑系统(PDI)。广泛应用于玻璃、塑料、机床、纺织等机械设备的润滑。 |

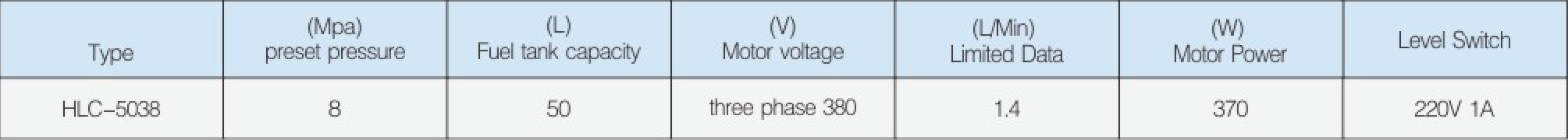

| Introduction to the working principle of the system After the lubricating pump station is connected to the working power supply, set the operation mode according to the “operation flow chart” of the program controller, so that the motor is energized, and the gear pump starts to work. The lubricating oil is output through the oil outlet filter. The maximum pressure of the system is set by the overflow valve (set at 8MPa when leaving the factory). The output lubricating oil enters into the storage oil in the quantitative distributor. When the quantitative distributor is filled with lubricating oil, the motor and electromagnetic reversing valve are de-energized, the system is unloaded,and the quantitative distributor injects the lubricating oil in the memory into the lubrication point to complete an oiling process. | 系统工作原理介绍润滑泵站接通工作电源后,根据程序控制器《运行流程图》设定运行方式,使电机通电,齿轮泵启动上班。润滑油通过出油过滤器输出。系统最高压力由溢流阀设定(出厂时设定为8MPa)。输出的润滑油进入定量分配器内的储油器。当定量分配器注满润滑油时,电机和电磁换向阀断电,系统卸载,定量分配器将内存中的润滑油注入润滑点,完成一次注油过程。 |

| 【Precautions】 | 【防范措施】 |

| • Dosing distributors should be installed as far as possible where the lubrication points are concentrated. The inner diameter of the main oil pipe must be ≥ ¢ 8. | • 计量分配器应尽可能安装在润滑点集中的地方。主油管内径必须≥¢8。 |

| • It is not allowed to install a check valve between the lubrication pump station and the quantitative distributor to prevent the system from being depressurized. | • 润滑泵站与定量分配器之间不允许安装止回阀,以防止系统泄压。 |

| • A 25u-125u oil filter should be installed at the oil outlet of the lubricating pump station to ensure that the system oil is clean and free of impurities. | • 润滑泵站出油口应安装25u-125u滤油器,保证系统油液清洁、无杂质。 |

| • Before connecting the metering dispenser, all pipes should be carefully flushed (or blown out) to decontaminate them and prevent dirt from entering the oil drain and lubrication points. | • 在连接计量分配器之前,应仔细冲洗(或吹扫)所有管道,以净化管道并防止污垢进入排油口和润滑点。 |

| • Before the test run, loosen the oil plug of the last oil drain of each oil circuit, start the pump station, drain the air in the system, and then tighten it, and carefully check the connections of the system, there should be no leakage. | • 试运行前,松开各油路最后一个放油口的油塞,启动泵站,排净系统内的空气,然后拧紧,并仔细检查系统的连接情况,不应有异常现象。泄漏。 |

| • In the lubrication system, all thread seals are not allowed to use raw tape. | • 在润滑系统中,所有螺纹密封件均不允许使用生胶带。 |

| • During the use process, the system should be regularly checked for leakage, and whether the indicator rod of the quantitative distributor is properly extended or not | • 使用过程中应定期检查系统有无泄漏,定量分配器指示杆是否正常伸出 |

@ 2026 Sino Solutions, All Rights Reserved.